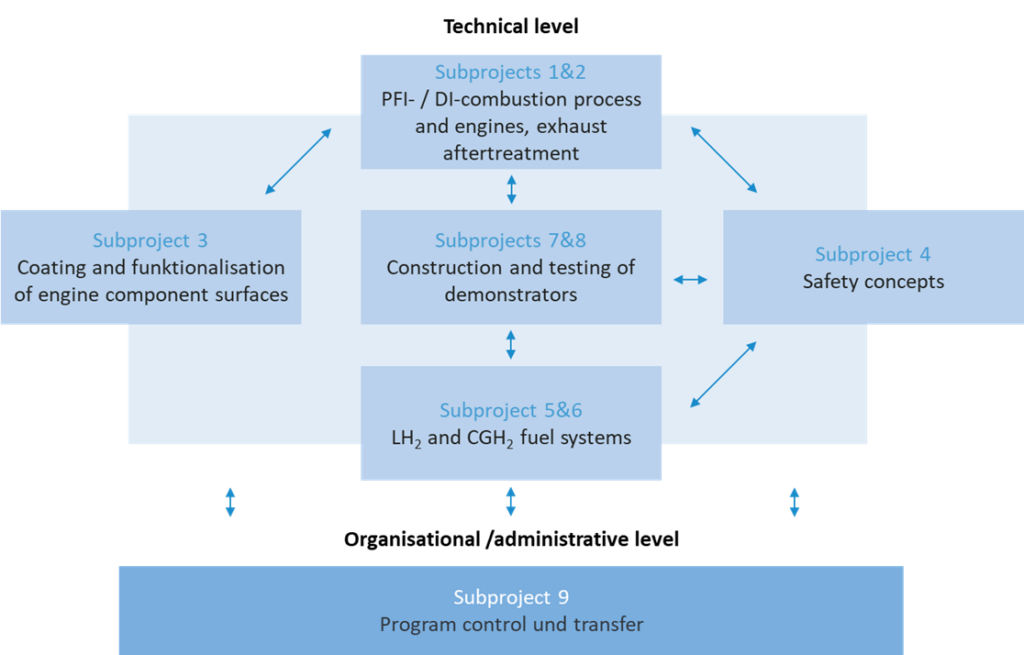

The project partners are combining their technological competencies and developing innovative individual solutions for a hydrogen-based powertrain system in a total of eight technological sub-projects. The individual solutions are tested, coordinated and combined into a functioning overall powertrain system. This will then be installed and prototypically tested in two different demonstrators – a Unimog and a tracked vehicle from the construction machinery sector. The special feature of the project is the systemic approach, which is reflected in three areas:

The first area relates to the parallel development of hydrogen combustion engines with port fuel injection (PFI) and with direct injection (DI), including the necessary engine components. This is particularly useful against the background of achieving high efficiency levels, but also coping with load dynamics in later field tests. In addition to the fundamental development work on the base engines and their components (e.g. exhaust aftertreatment systems, injectors or sensors), their consistent optimisation on the basis of extensive tests is another focus of the project.

The second area in which the systemic approach is evident concerns the design of the hydrogen supply on the commercial vehicle. In the project, systems for compressed gas storage of hydrogen (CGH2) and liquid hydrogen storage (LH2) are being developed and evaluated in parallel. Both have specific advantages and disadvantages and require innovative solutions (e.g. on-board compressed gas generation from liquid hydrogen).

Finally, the systemic approach is also evident in a third area: the consideration of the operating conditions of hydrogen-based propulsion systems. The focus of the planned project is the development of a new type of hydrogen-based powertrain system, the design of which is geared to the operating conditions of different commercial vehicles and which, for example, has to cope with widely varying levels of load dynamics in real-world use. In the specific case of the Unimog, this means that the hydrogen engine must not only drive the vehicle, but also supply energy to the attachments in the field test.