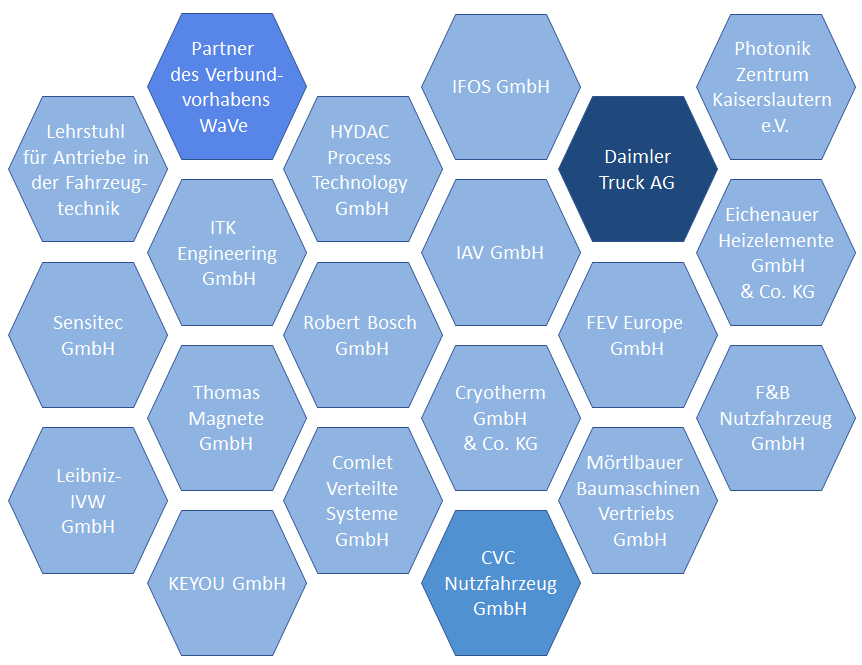

The joint project funded by the BMWK is being conducted by the following 19 partners from industry and research. Daimler Truck AG is the leader of the consortium. The Commercial Vehicle Cluster – Nutzfahrzeug GmbH is responsible for the administrative management.

The commercial vehicle manufacturer Daimler Truck AG, a subsidiary of Daimler AG, produces the Mercedes-Benz Antos, Arocs, Atego and the world’s most successful heavy-duty truck Actros as well as the Mercedes-Benz Special Trucks Econic, Unimog and Zetros at the Mercedes-Benz plant in Wörth. Daimler Trucks is the world market leader in the field of medium and heavyduty trucks with a gross vehicle weight of over 6 tons. Within the framework of the project, this partner will primarily be involved in the development and optimisation of the PFI/DI engines and their exhaust gas aftertreatment and the testing and integration of the developed engines and the on-board hydrogen supply systems in the demonstrators provided by the company and in other demonstrators.

Commercial Vehicle Cluster – Nutzfahrzeug GmbH

The Commercial Vehicle Cluster interlinks partners from business, science and politics in order to strengthen the southwest of Germany, especially Rhineland-Palatinate, as a leading competence centre for the commercial vehicle industry. To achieve this goal, the CVC implements initiatives that sustainably strengthen the innovation and competitiveness of the commercial vehicle industry. The promotion of technological competencies, the networking of partners along the entire value chain, the design of strategic innovation processes and the cultivation of dialogue between science, business and politics are key areas of action in this context. As early as October 2019, the CVC drew up a hydrogen strategy and, in the course of this, developed the project idea for the WaVe project and drew up the corresponding project outline. Furthermore, the CVC coordinated the funding application with the Federal Ministry for Economic Affairs and Energy and is now responsible for the administrative management of the project.

comlet Verteilte Systeme GmbH is a specialised development service provider in the field of embedded systems and develops individual systems and components up to complete products. Comlet is certified according to DIN EN ISO 9001:2008 and offers development services as on- and off-site support. Within the scope of the project, comlet Verteilte Systeme GmbH will be primarily involved in the creation and maintenance of a digital twin across almost all project modules and thus provide significant support for the project.

Cryotherm Energy Systems provides the cryogenic and technical expertise for customers working on advanced energy solutions. With decades of experience in cryogenic liquefied gas applications, Cryotherm is powering the liquefied gas market and contributing to a wide range of industries by offering LNG/hydrogen storage and transport tanks, transfer lines and systems. As part of the project, Cryotherm GmbH & Co. KG will primarily be involved in the area of on-board hydrogen supply with liquid hydrogen. Corresponding components will be developed and optimised in order to test them in the demonstrator.

Eichenauer Heizelemente GmbH & Co. KG

The family business Eichenauer is a specialist in the development, production and distribution of electrical heating systems. As a development partner for customers in the automotive, household appliance and industrial systems sectors, Eichenauer uses the technological diversity of the company’s own know-how, from self-regulating PTC heating systems to open wire heaters and soldered aluminium-stainless steel heating elements. As part of the project, Eichenauer Heizelemente GmbH & Co. KG will primarily be involved in the area of hydrogen supply, whether with gaseous or liquid hydrogen, and develop the necessary heated components for the prototype drive systems and their testing.

F&B Nutzfahrzeug-Technik GmbH is engaged in the equipment and conversion of commercial vehicles. In this field, F&B has many years of experience in close cooperation with Daimler AG, branches, representatives of Daimler AG and reputable attachment manufacturers. Within the framework of the project, F&B Nutzfahrzeug-Technik GmbH will primarily be involved in the construction and conversion of the demonstrators and develop solutions to integrate the prototype drive systems accordingly.

Development service provider in the development of combustion engines and vehicle technology. It designs and develops engines for appliances, passenger cars and commercial vehicles, but also for ships and locomotives – from the sketch to the start of production. Within the framework of the project, FEV GmbH will primarily be involved in the development and optimisation of PFI combustion processes, the engines and their exhaust gas aftertreatments, in order to make them available for the testing in the demonstrators.

For more than 30 years, HYDAC Process Technology GmbH has been engaged in the production of special filter elements for process technology – with a focus on the production of filter elements made of complete stainless steel in medical technology and process technology. Within the scope of the project, HYDAC Process Technology GmbH will primarily be involved in the area of on-board hydrogen supply and develop appropriate filter solutions to ensure the required purity of the hydrogen for combustion.

IAV GmbH Ingenieurgesellschaft Auto und Verkehr

IAV GmbH Ingenieurgesellschaft Auto und Verkehr is one of the world’s leading engineering service providers to the automotive industry. Its core competencies include production-ready solutions in all areas of electronics, powertrain and vehicle development. As a developer of innovative technology, IAV works with all big names in the automotive and research world. As part of the project, IAV GmbH will be involved primarily in the development and optimisation of DI combustion processes, engines and their exhaust gas aftertreatment systems, which will then be made operational for testing in the demonstrator.

Institut für Oberflächen- und Schichttechnik GmbH (IFOS)

IFOS is concerned with the application and development of modern techniques for the chemical, structural and topographical analysis of surfaces, thin films and solids. The main areas of work are research and development in the field of instrumental surface analysis, contract analysis, application of instrumental surface and layer analysis to problems in research and technology as well as transfer to industry and business. Within the framework of the project, the IFOS will primarily be involved in the area of coating and functionalising the surfaces of engine components for their testing.

ITK Engineering GmbH is a development service provider with customers in the automotive, aerospace and medical technology sectors. It has been a subsidiary of Robert Bosch GmbH since 2017. In addition to consulting and development support, the company provides system solutions in the areas of software engineering, embedded systems, model-based development and testing, control engineering and signal processing. Within the scope of the project, ITK Engineering GmbH will primarily be involved in the development and refinement of safety concepts for the reliable operation of a hydrogen-based drive system on the test stand as well as in the demonstrators.

KEYOU is a high-tech company from the Clean Mobility sector that develops innovative hydrogen technologies, special components and combustion processes for engine and vehicle manufacturers, enabling conventional engines to be transformed into emission-free hydrogen engines – without major modification of the basic engine. Within the framework of the project, KEYOU GmbH will primarily be involved in the development and optimisation of PFI combustion processes, the engines and their exhaust gas aftertreatments, in order to subsequently make them available for testing in the demonstrators.

Leibniz-Institut für Verbundwerkstoffe GmbH

The Leibniz Institut für Verbundwerkstoffe (Composite Materials) (IVW) is a non-profit research institution of the state of Rhineland-Palatinate and the Rhineland-Palatinate Technical University of Kaiserslautern-Landau (RPTU). It studies the fundamentals for future applications of composite materials, which are of great importance for the mobility of the future and other areas. New materials, construction methods and manufacturing processes are being investigated and customised for the respective product requirements. Within the framework of the project, the Leibniz Institute for Composite Materials GmbH will primarily be involved in the area of on-board hydrogen supply with gaseous hydrogen and will develop solutions for storing hydrogen at high pressures, whether for alternating tank or stationary systems.

Mörtlbauer Baumaschinenvertriebs GmbH

The family-run company represents the Hyundai and SkanCraft brands with its own specialist workshop. Mörtlbauer has a large rental fleet of construction machinery and attachments for every type of machine. A stock of over 900t of wear parts makes it the largest wear parts dealer in the German-speaking region. In addition, Mörtlbauer develops customised products in cooperation with customers, such as tracked excavators with electric drives. Within the scope of the project, Mörtlbauer Baumaschinenvertriebs GmbH will primarily be involved in the area of demonstrator testing of the mobile working machine. For this purpose, it will provide a tracked vehicle as a demonstrator and participate in the integration, testing and further development of the drive systems for the mobile working machine.

Photonik-Zentrum Kaiserslautern e. V.

The Photonik-Zentrum translates developments in modern optics and laser physics into industrial applications. The purpose of the association is the targeted promotion of scientific and technological progress in the fields of optical technologies, laser technology and non-linear optics with the aim of promoting the application and dissemination of these technologies in dialogue with science and industry and creating the foundation for making the innovation potential of these technologies economically viable. Within the framework of the project, the Photonik-Zentrum Kaiserslautern e. V. will primarily be involved in the area of coating and functionalising the surfaces of engine components for their testing, and will also analyse them in order to derive optimisation potential for surface treatment.

Robert Bosch GmbH is part of the Bosch Group and with its automotive division the world’s largest automotive supplier. With wide-ranging technical expertise, Bosch develops innovative mobility solutions in the areas of hardware, software and service. Robert Bosch GmbH is one of the companies with the highest research intensity in Germany. Within the framework of the project, Robert Bosch GmbH will primarily contribute to the development and optimisation of injectors and spark plugs for PFI and DI engines.

Sensitec is a leading manufacturer of magnetoresistive (MR) sensors for non-contact measurement of angle, length, position, current or magnetic field. Areas of application for the sensors include the automotive sector, automation, renewable energies, e-mobility, medical technology and aerospace. Within the framework of the project, Sensitec GmbH will primarily be involved in the development and optimisation of PFI and DI combustion processes / engines and will develop solutions for measuring valve movement in combustion engines.

The family business Thomas Magnete develops and manufactures electromagnetic and fluidic actuator systems for the automotive and mobile hydraulics industries as well as medical products. Its customers include premium manufacturers in the automotive industry, leading international manufacturers of vehicles and mobile machinery, and system suppliers. Within the framework of the project, Thomas Magnete GmbH will primarily be involved in the area of hydrogen supply, whether with gaseous or liquid hydrogen, and will, for example, develop shut-off and control valves for the prototype drive systems and their testing.

RPTU – Institute of Vehicle Propulsion Systems (LAF)

The LAF is assigned to the Department of Mechanical and Process Engineering. The focus of research and teaching is on R&D of low-emission and resource-saving vehicle powertrains – this includes component development and optimisation for internal combustion engines and alternative powertrains as well as the development and research of new combustion processes and their interaction with the components of the (hybrid) powertrain – and the testing of alternative fuels. Within the framework of the project, the LAF will primarily be involved in the development and optimisation of PFI/DI combustion processes, engines and their exhaust gas aftertreatment, develop basic drive systems on the test stand and further develop and optimise these in conjunction with the demonstrator tests.